Press. Form. Laser. Weld. Punch. Cut. Bend. Paint. Machine.

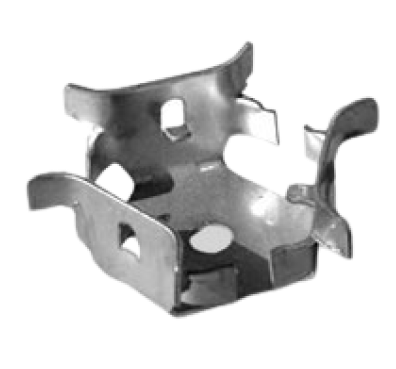

We provide a total component solution from the smallest custom part to complex welded structures up to 10 tonnes, our experienced team specialises in providing innovative engineering solutions. We also design and manufacture an extensive range of prefabricated parts for industry.

Materials

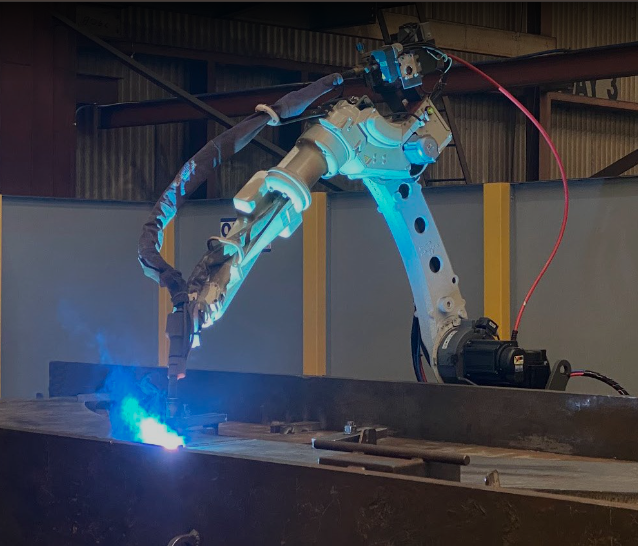

We're going Robotic. Pressform are excited to introduce our Panasonic robot welding system.

Pressform specialise in welding automation, utilising Panasonic’s Industrial Robot Welding systems with a reach of 2000mm. Our focus is Robotic MIG and TIG processes for Mild Steel, Stainless steel, Aluminium and hard-facing industries. We create jigs for your parts for repetitive production of your components, ensuring productivity is maximised.

Why choose PRESSFORM?

We provide a total component solution from the smallest custom part to complex, welded structures up to 10 tonnes. We offer all forms of welding, laser cutting, rolling, CNC punching and perforating, bending, stamping, hot forming, CNC machining, profiling and high definition plasma cutting and we have our own highly experienced Metalurgist on staff, so we work confidently and consistently in all metals including stainless, nickel alloys, aluminium, copper, brass, carbon steels, quench and tempered steels. We design , build and maintain all our tooling in our own factory which ensures our products are high quality and cost effective.

Can PRESSFORM design parts for me?

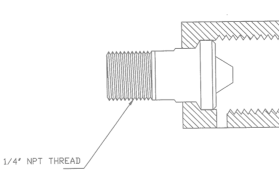

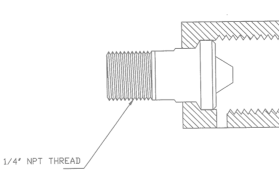

Our experienced team specialises in providing innovative engineering solutions for new products and will work out the most efficient manufacturing method to deliver your product on time and on budget. We will manufacture any component small or large, from washers, pipe supports, machined and threaded components, production welded brackets, clamps and pump skids to balustrades, handrails, lintels, motor vehicle parts and valve components.

Why should I choose CNC machining?

No one knows metal like we do. We have a highly experienced in-house Metallurgist, so we work confidently and consistently with all materials including austenitic & ferritic stainless steel alloys, nickel alloys, copper, brass, aluminium, and carbon steels (including forming, high tensile & boiler grade).

How quick is delivery?

We provide a cost effective delivery service with our Hino Truck with 8.2 tonne load capacity & 7.6 x 2.5 metre tray.

- Hydraulic Powered Press 630 tonne with deep draw die cushion capacity

- CNC Turret Press – 30 tonne

- CNC Plasma Cutting with nesting software

- 3Kw & 6Kw Fibre Laser Cutting Machines cutting up to 25mm thick

- Press Brake 400 tonne x 4000mm long Press Brake 150 tonne x 3600mm long

- Automatic scissor style Bandsaw with feed table and full capacity hydraulic overhead bundling

- Punching 0.5mm to 20mm thick

- Bending 2.5 to 150 tonne, fast mechanical and metered hydraulic

- Cropping 250mm x 10mm, 75mm x 20mm • Forming & deep drawing

- CNC Plate Rolling 10mm x 1800mm wide to 32mm x 75mm, including cone sections

- Complete Welding (GMAW, GTAW, MMAW, SAW) and fabrication capabilities

- Robot Welding System with 2000mm arm reach for stainless & mild steel welds

- Stud Welding: Including Stud Production and Testing • CNC Milling: Machining Centres

- CNC Turning: Bar Feed Lathes (72mm max for bar feed)

- Tool Making and General Machining (Milling, Surface Grinding, Turning, Drilling and Threading)

- Painting: Electro Static Painting capabilities (2 pack, Enamel)

- Dual Head Semi-Automatic Welding capabilities

- Lifting Capacity 10 tonnes overhead cranes

- Post production finishing services: Sand Blasting, Rumbling, Painting, Powder-coating, Galvanising, Anodising, Electroless Nickel, Zinc or Chrome Plated.

Get an obligation FREE quote!

Request for a personalized quote for your problem. We will help guide you through the journey to solve all your pending criteria. Free consult available to first time customers.